Because kelly system is designed to operate in the negative zone the vents must be positioned on the perimeter edge.

Negative pressure roofing system.

Loose laid air pressure equalization system.

The kelly system is a passive system that simply transfers the negative pressure while v2t is an active system that generates greater negative pressures under the membrane than what is being exerted on the roof surface.

Continuous self drying of wet roofs with wind vented negative pressure system.

Negative pressure is generated and maintained by a ventilation system that removes more air from the room than air is allowed into the room.

A very small amount of positive pressure is ideal for a building but too much can cause damage.

Constant daily pressure puts strain on hot air welds induction welds and adhesives.

Apparently the negative pressure system is secured only at the perimeter the rest being loose laid i can t imagine how the mod bit versions of this idea work but the literature claims they do.

The wv roof assembly creates a continual drying of the roof substrate.

The second difference is the positioning and principles of operation of the two systems.

Negative pressure is then applied to the dome starting at an initial pressure of 15 pounds per square foot psf.

Water moisture damage within the roof turns to vapor in low pressures created by the wind vent system.

Protan s vacuum system is based on the principle of anchoring the membrane by creating negative pressure in the layer between the membrane and the airtight substrate when exposed to wind loading.

Poor design of cool roofs in ashrae climate zones 4 and higher have resulted in the unintended consequence of condensation below the membrane a result of.

Air is allowed into the room through a gap under the door typically about one half inch high.

Additionally designers should be aware of the possible negative impacts of using cool roofing that may result in unintended consequences.

The negative pressure test utilizes a five foot by five foot dome that is placed over the roofing membrane surface.

The negative pressure roofing system is referred to as a wind vented roof and is proven in thousands of roof installations.

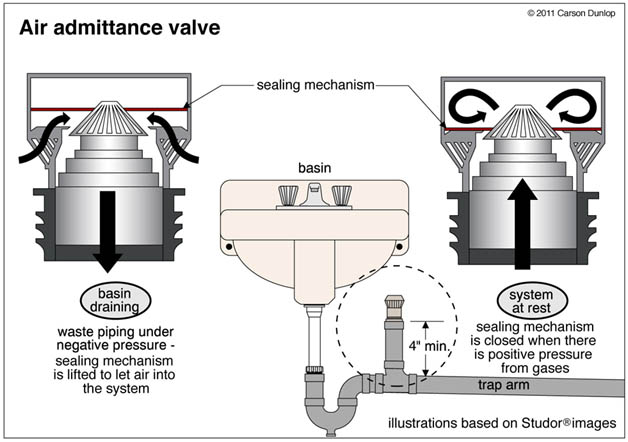

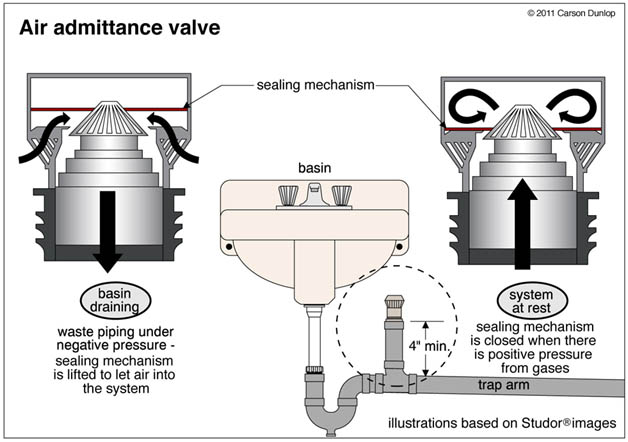

Upward migration of water vapor is vacuumed out of the roof assembly through one way valves placed in wind vortex intensity areas of a building perimeter.